The word Ceramic was coined from the Greek word keramikos which means of pottery. Advanced Ceramics are primarily called as inanimate and non-metallic substances, shaped and solidified by heat in high heat. Cement, Glass, brick, are all samples or the derivatives of Ceramics. Prior to the development in ceramics, there was a traditional process of generating ceramics. It is one of the traditional human mechanisms, utilizing clay, molding and solidifying at high temperatures to generate ceramics. Earlier ceramics indicates to pottery, stone tools, porcelain and bone china.

The manufacture of earlier Advanced Ceramics dates as earlier as thousands of years. As per archaeologists, the ancient pottery developed and invented by man is 20,000 years old. As technology has enhanced through the years, so have the substances and patterns utilized in traditional ceramic manufacture. Apart from the traditional ceramics, advanced ceramics has enhanced its meaning and position and has gone yonder the barriers of clay-based and pottery, and integrating inanimate non-metallic materials.

The Advanced Ceramics Market has witnessed remarkable growth in recent years, driven by advancements in technology, increasing demand for high-performance materials, and the ever-evolving applications across various industries.The Global Advanced Ceramics Market Was Valued At US$ 80,442.64 Mn In 2021 And Is Forecast To Reach A Value Of US$ 122,101.00 Mn By 2030 At A CAGR Of 6.72% Between 2022 And 2030.

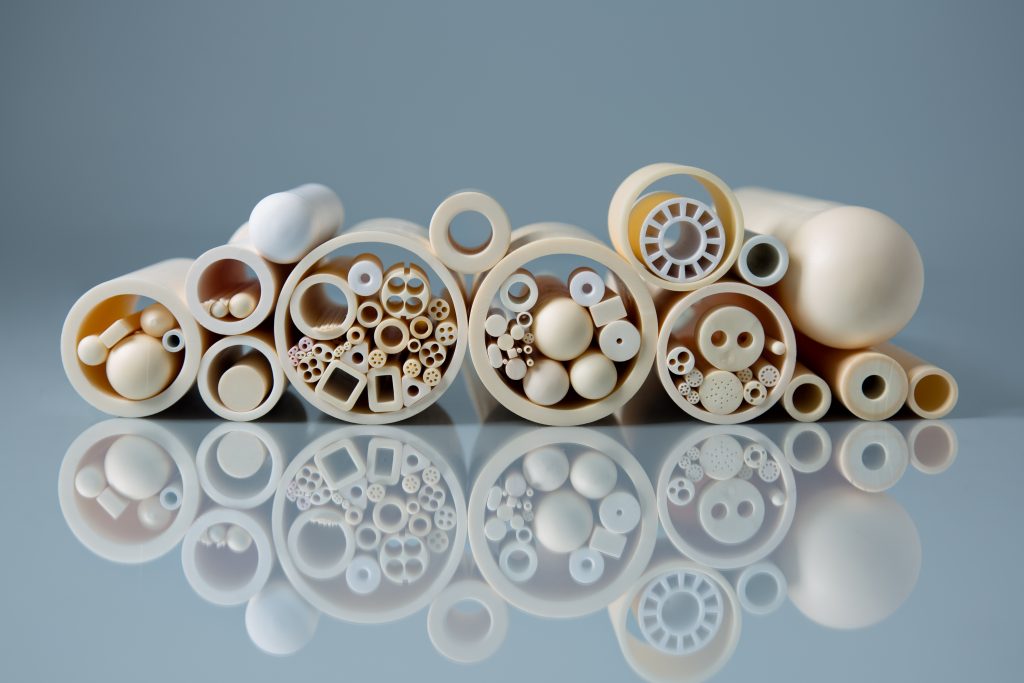

Advanced ceramic materials perform a big part in the growth of a vast variety of production industries, such as production of metal and processing, aerospace, electronics, automotive, telecommunications, medical, and manufacturing transportation. Having recognized the difference amongst traditional ceramics and advanced ceramics, one should understand the kinds of advanced ceramics, their special features and their uses. Alumina is also called as aluminum oxide, Alumina is one of the most vastly utilized advanced ceramic materials.

This white, well-balanced substances had been utilized for decades in technical parts and electrical compounds, due to its several standards of purity, rigidity, and high melting point that is utilized as a refractory substance. This advanced ceramic substances also has other imposing attributes, such as a huge level of technical potency, high oxidation resistance, exclusive wear resistivity, high compressive potency, and low density. All of the properties make it one of the robust and most commonly utilized advanced ceramic materials. Alumina ceramic is utilized in the manufacture of pump seals, wear and heat resistivity liners, electrical insulators, lithium-ion batteries, armor protection, glass, bearing, and others.

Zirconia, or zirconium dioxide, is found in white or black color, owns a wide array of desirable features, and is totally chemically unreactive, making it appropriate for usage in various organizations. Its outstanding features, such as superior wear and abrasion resistivity, low thermal conductivity, huge thermal shock resistivity, high mechanical potency, and impressive oxidation resistivity, making it one of the robust and most vastly researched ceramic materials. Due of the unique features, few of which are same to alumina, zirconia is utilized in the manufacture of cutting devices and tools, aerospace, microengineering, clinical, electronics, filters, oxygen gas sensors, and others.

This specific technical advanced ceramic is sporadic in nature and mostly observed in the mineral moissanite. Silicon carbide was first revealed by an American scientist, Dr. Edward Goodrich Acheson. It is the only chemical component of carbon and silicon and creates very robust and hard metals. It was initially created by a high-temperature electro-chemical reaction of sand and carbon, leading a product that is utilized as a refractory resistor, abrasive, and electric resistor.

The usage of Advanced Ceramics are various and diverse. They are utilized as an alternative for metals, alloys, and amalgams in several industries such as electrical & electronics, vehicle, aerospace, and defense. Advanced ceramics show superior corrosion resistivity, which aids decrease maintenance price and interruptions owing to equipment outbreak. This is particularly essential in extreme surroundings such as oil field and military & aerospace uses. In Addition, they also have completely low thermal expansion than the metals or aluminum.