Ethyl Alcohol as a Base

Ethanol, also known as ethyl alcohol, is an organic compound with the formula C2H5OH. It is the defining member and simplest representative of the alcohol chemical class and is common to many agricultural and industrial processes. As a base chemical, ethanol serves as a precursor to numerous industrial chemicals through various reaction pathways involving substitution or elimination of its hydroxyl group.

Ethyl Acetate Production

One of the most important Ethanol Derivatives is ethyl acetate. Ethyl acetate is used as a solvent and as a synthetic fruit flavoring and fragrance. It is produced industrially through the Fischer esterification reaction of ethanol and acetic acid. This reversible reaction occurs readily in the presence of an acid catalyst like concentrated sulfuric acid. Ethyl acetate has a characteristically pleasant, fruity odor and is used to provide artificial fruit flavors to foods and beverages. Global production of ethyl acetate exceeds 1 million tons per year.

Ethylene and Diethyl Ethers

Ethanol can react with itself to form ethers through dehydration reactions. When two ethanol molecules lose a water molecule each, diethyl ether is produced. Diethyl ether was formerly used as a general anesthetic but has been replaced by safer alternatives. When a single ethanol molecule reacts to eliminate water, ethylene (C2H4) is formed through an elimination reaction. Ethylene is a petrochemical feedstock to make various plastics and resins through polymerization reactions. Diethyl ether and ethylene production from ethanol amounts to hundreds of thousands of tons annually.

Ethylene Glycol Synthesis

Ethylene glycol, also known as MEG for monoethylene glycol, is a very important raw material for polyester fiber and resin production in Ethanol Derivatives. It can be synthesized by the reaction of ethanol with ethylene oxide. Ethylene oxide adds across the hydroxyl group of ethanol in an exothermic reaction to form the monoether product. Ethylene glycol has a molecular formula of C2H6O2 and is a clear, colorless, odorless and sweet-tasting liquid. Global ethylene glycol production exceeds 20 million tons per year, providing critical feedstock for polymers like polyester and antifreeze formulations.

Higher Chain Alcohols from Ethanol

Catalytic hydration of ethylene, produced from ethanol, provides an industrial route to higher chain aliphatic alcohols. Ethylene reacts with steam in the presence of an acidic catalyst to form a mixture of alcohols with chain lengths of C2-C10+. These alcohols find applications as detergent alcohols, plasticizers and additives. Important members include 1-butanol, 2-butanol, 2-ethylhexanol, octanol and decanol. Global production capacity for higher alcohols now exceeds 5 million tons annually. Ethanol thus serves as an important C1 building block in alcohol synthesis.

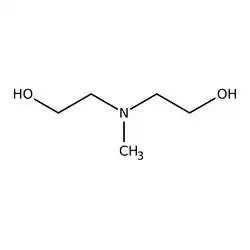

Ethylamine Production

Ethylamine, also known as ethanolamine, is an important intermediate chemical produced through reacting ethanol with ammonia. This reaction is conducted at elevated temperatures and pressures in the presence of catalysts like silica-alumina. Ethylamine has found increasing use as a solvent, in the production of agrochemicals and as a component in personal care products and shampoos. World ethylamine capacity exceeds 1 million tons per year. The amine functionality introduced by aminating ethanol boosts its practical utility as an industrial feedstock chemical.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it

About Author - Vaagisha Singh

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups. LinkedIn

by

by