Concrete is one of the most widely used man-made construction material across the globe. However, conventional concrete has certain limitations like low tensile strength, brittle behavior and cracking tendencies.

What is Fiber Reinforced Concrete?

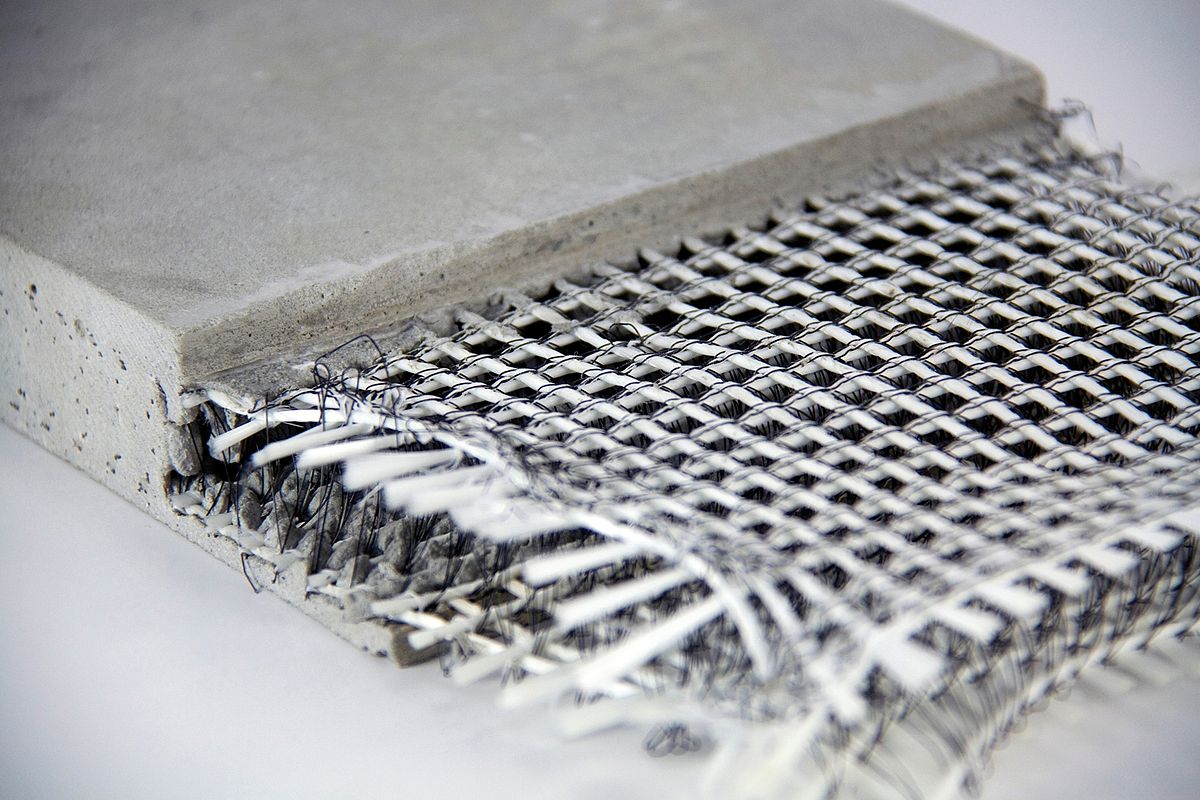

Fiber reinforced concrete is basically a cement-based composite material wherein discontinuous discrete fibers are added to conventional concrete mix. The commonly used fibers include steel fibers, synthetic fibers (made of nylon, polypropylene, polyvinyl alcohol etc.), glass fibers and natural fibers. When uniformly dispersed in concrete matrix, these fibers act as crack arrestors and control the crack propagation. Thus, fiber reinforced concrete exhibits higher tensile strength, improved ductility, resistance to impact and shatter resistance as compared to plain concrete. Different types of fibers provide varied properties to the concrete.

Benefits of Fiber Reinforced Concrete

The addition of fibers to concrete matrix results in enhancement of many desirable material properties which include:

– Higher tensile strength and flexural strength: Fiber Reinforced Concrete exhibits 2-5 times higher post-cracking residual tensile strength and flexural strength compared to plain concrete.

– Improved ductility: Fibers prevent sudden catastrophic failure even after cracking and allow gradual deformation without crumbling. This improves toughness and ductility.

– Reduced permeability: Closely spaced micro-cracks formed by fibers have sealing effect which reduces permeability of concrete.

– Increased abrasion and impact resistance: Fibers absorb energy of suddenly applied forces and reduces incidence of cracking under impact and abrasion.

– Reduced shrinkage cracks: Uniform dispersion of fibers controls shrinkage cracking tendencies during hardening of concrete.

– Enhanced durability: Improved impermeability and crack-control properties of FRC enhance durability of concrete structures.

Applications of Fiber Reinforced Concrete

Due to impressive material enhancements offered, FRC is increasingly being used in various construction applications. Some of the major applications of FRC are:

– Industrial floors: FRC floors exhibit high abrasion and impact resistance, making them suitable for heavy duty industrial floors.

– Overlays: FRC is used as thin bonded overlay on existing concrete surfaces for repair and rehabilitation.

– Slabs/pavements: FRC slabs and pavements are more durable and crack-resistant compared to plain concrete.

– Tunnel linings: Flexural strength and impact resistance of FRC make it suitable material for tunnel lining segments.

– Pre-cast products: Manufacture of pre-cast elements like fence panels, poles, pipes etc. is enhanced using fibers.

– Repairs: Different types of repair works involving cementitious materials utilize fiber reinforced systems.

Guidelines for Fiber Reinforced Concrete Design and Production

Proper design mix proportioning and production methods are important for realizing potential benefits of fiber reinforcement in concrete. Some of the key guidelines are:

– Fiber dosage: Dosage depends on fiber type and structure but typically ranges from 10-80 kg/m3 of concrete. Higher dosage may cause workability and placement issues.

– Fiber dispersion: Uniform dispersion and distribution of fibers in fresh concrete mix is critical. Entrainment aids and high shear mixers help ensure dispersion.

– Workability: Workability is reduced with addition of fibers. Addition of appropriate chemical and mineral admixtures helps maintain adequate workability.

– Curing: As FRC hydrates and gains strength at a faster rate, proper moisture curing must be ensured to develop long term structural properties.

– Placement techniques: Placement methods should avoid segregation of fibers from mix during transportation and compaction. Pumping and molding require adjustments.

Using standardized mix design and production protocols, fiber reinforced concrete can unlock its true potential in construction. With further research, it is expected to become preferred concrete solution in near future.

*Note:

- Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it