Hydroelectric power is one of the most reliable and sustainable sources of renewable energy. With rising concerns over climate change and environmental sustainability, many countries are pushing for greater adoption of hydroelectric power. At the heart of any hydroelectric power plant lies the hydro turbine generator unit which converts the kinetic energy of flowing water into electric power. In this article, we will take a detailed look at how hydro turbine generator units work and their importance in the generation of clean hydroelectric power.

Types of Hydro Turbine Generators

There are mainly two types of hydro turbine generators used in hydroelectric power plants depending on the design and operating characteristics – impulse turbines and reaction turbines.

– Impulse turbines: Impulse turbines like Pelton wheels utilize the pressure energy of flowing water to spin the runner. They are suitable for high head and low flow applications. Water jets emerge from nozzles and impulse the buckets of Pelton wheels causing them to spin at high speeds.

– Reaction turbines: Reaction turbines like Francis and Kaplan turbines utilize both the pressure and kinetic energy of flowing water. They feature runner blades enclosed in a stationary casing. Water pressure causes the blades to spin via Newton’s laws of motion. They are more suited for lower head but higher flow applications.

Components of a Hydro Turbine Generator Unit

The key components of a hydro turbine generator unit include:

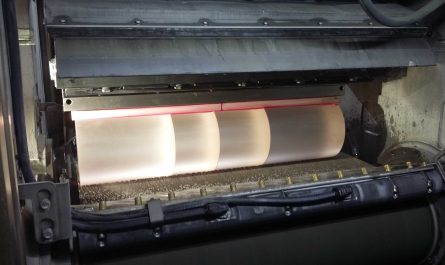

– Turbine: It is the heart of the unit that converts hydraulic energy (kinetic and pressure energy of water) into mechanical rotational energy. Common turbine types used are Pelton, Francis and Kaplan turbines.

– Generator: It is a large rotating electric generator that converts the mechanical rotational energy of the turbine into electric energy. Synchronous generators are commonly used in hydroelectric applications.

– Shaft: It transmits the rotational mechanical power from the turbine to the generator. Modern units feature a single horizontal shaft linking the turbine and generator for maximum power transfer efficiency.

– Guide vanes: Adjustable guide vanes help direct the water flow into the turbine runner for optimum efficiency under varying head and flow conditions.

– Turbine housing: It houses and supports the entire turbine assembly including stationary components like guide vanes and runner casing. It is designed to withstand very high water pressures.

– Bearings: High-capacity bearings support the heavy rotating components like shaft and allow smooth rotation with minimal friction losses. Lubrication systems ensure long operational life of bearings.

Working of a Hydro Turbine Generator Unit

The working process of a hydro turbine generator unit can be summarized as follows:

– Water is captured from a reservoir/dam/river and directed through a penstock pipe towards the turbine housing under hydraulic head pressure.

– Guide vanes, dependent on the load demand, direct the water flow onto the turbine runner blades mounted on the rotating shaft.

– Impact or pressure of water causes the turbine runner blades to spin at high speeds, typically ranging from 75-600 RPM depending upon the turbine model.

– The high torque rotational energy of the turbine shaft is transferred to the generator through a single horizontal driveshaft coupling the two.

– As the generator rotor spins inside the stationary stator windings due to the mechanical energy input, electricity is generated through electromagnetic induction process.

– The generated electricity is then stepped up to transmission level voltages using transformers and fed into the utility grid for distribution.

– Any excess water post power generation is discharged downstream without affecting the aquatic life in a environment-friendly manner.

Applications and Benefits of Hydroelectric Power

Some key applications and benefits of clean hydroelectric power generated through hydro turbine generator units include:

– Base load power generation: Hydropower is a reliable baseload renewable source that can generate bulk power continuously to meet demand.

– Peak load handling: Output can be increased/decreased very quickly based on varying electricity demands. Hydropower supports green grids by complementing renewable intermittent sources.

– Low maintenance costs: Modern hydroturbine units have operational lifespans of 30-50 years and require relatively low maintenance compared to other generators.

– Flood control: Reservoirs act as storage zones helping regulate river water flow and preventing downstream flooding during heavy rains/snow melts.

– Water supply: Hydropower reservoirs serve the dual purpose of providing drinking/irrigation water in many areas.

– Rural electrification: Mini/micro hydel projects effectively deliver power to remote off-grid mountainous regions.

– Carbon free energy: Hydropower is one of the cleanest energy sources without any fossil fuel combustion or greenhouse gas emissions during operations.