Polyurethane Prepolymer: Key Properties and Applications

What are Polyurethane Prepolymers?

Polyurethane prepolymers refer to partially polymerized materials that are used as intermediates in the production of polyurethane products. They are produced by reacting a polyol such as a polyether or polyester with excess diisocyanate. The prepolymer reaction stops before it is fully polymerized, resulting in an intermediate product with reactive isocyanate groups still available for further reaction.

Chemical Structure and Properties

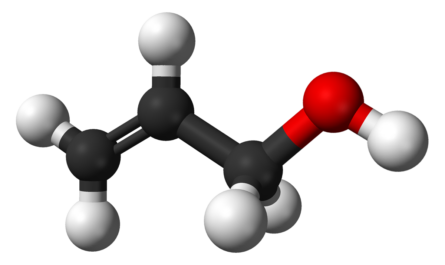

Polyurethane prepolymers have a linear or branched macromolecular structure composed of polyol backbones with diisocyanate ends. The polyol backbones can be polyetherols derived from ethylene oxide, propylene oxide or tetrahydrofuran. Polyesters such as adipate or phthalate polyesters are also commonly used. Excess amounts of diisocyanates like toluene diisocyanate (TDI) or methylene diphenyl diisocyanate (MDI) are reacted so that isocyanate groups remain at the end of the polymer chains.

This partially polymerized structure gives prepolymers unique properties compared to fully polymerized polyurethanes. They are low-viscosity liquids or soft solids at room temperature due to their linear structure. The presence of unreacted isocyanate groups allows them to further react and chain extend or crosslink when compounded with other ingredients. This makes them thermoplastic materials that can be molded or cast into flexible foams, elastomers or coatings.

Production of Flexible Foams

One of the major applications of polyurethane prepolymers is in the production of flexible foams. In this process, the prepolymer is reacted along with polyols, water, catalysts and other additives using a foaming technique. Water reacts with the isocyanate ends of the prepolymer, producing carbon dioxide gas that gets trapped in the polymer matrix as it forms.

Common flexible foam products include slabstock foams used in furniture, automotive seats, mattresses and carpet underlay. Molded flexible foams are used in packaging, gaskets, automotive applications and thermal insulation. The properties of the final foam can be controlled by adjusting the prepolymer structure, indices and additives used. Flexible foams offer benefits like comfort, resilience, cushioning and Sound dampening.

Elastomer Production

Polyurethane prepolymers with low functionalities are widely used to produce elastomers with rubber-like flexibility and resilience. In elastomer production, the prepolymer is extended and crosslinked by reacting it with curatives like ethylene diamine or cycloaliphatic diamines. The crosslinking reaction results in the formation of a three-dimensional polymer network structure responsible for the elastic properties.

Common elastomer products include adhesives, sealants, coatings and membranes with high tear strength and abrasion resistance. Prepolymer-based elastomers see applications in industries like footwear, automotive, wires and cables. Their mechanical properties can be customized for different end-uses by controlling the prepolymer molecular weight and degree of crosslinking.

Coating Applications

Polyurethane prepolymers are important raw materials for producing coatings with protective and decorative functions. In coating formulations, the prepolymer provides adhesive strength to surfaces through its isocyanate reactivity. It is mixed with polyols, catalysts, pigments and additives before application. Curing occurs when the isocyanate groups react with themselves or crosslinkers like moisture in air to form a networked polymer film.

Common polyurethane coating types include single-component moisture-cured and two-component crosslinkable formulations. They deliver characteristics like chemical resistance, flexibility, abrasion resistance and weatherability. Prepolymer-derived coatings see widespread use in wood finishes, concrete sealers, automotive and industrial applications. Their versatility makes them suitable for both interior and exterior surfaces.

Advantages and Limitations

Some key advantages of using polyurethane prepolymers include their low viscosity, storage stability, reactive functional groups and ability to produce a range of thermoplastic and thermoset materials. Their mechanical properties can also be readily modified for different end-use applications. However, prepolymers do have certain limitations such as moisture sensitivity of stored products and stringent safety requirements around their isocyanate reactivity.

Strict quality control protocols must be followed during production, transportation, storage and processing due to reactivity issues. Hydrolytic stability can degrade over long storage periods in moist environments if appropriate packaging is not used. Despite challenges, polyurethane prepolymers remain important intermediates for manufacturing flexible and rigid foams, elastomers, coatings and adhesives on an industrial scale. Continuous research further expands their structure-property relationships and end-use potential.

In conclusion, polyurethane prepolymers are partially polymerized intermediates containing unreacted isocyanate groups that make them suitable for producing a variety of plastic and elastomeric materials. Their unique reactivity profile and properties contribute to versatile applications in industries like furniture, footwear, automotive, construction and packaging. Precautions during handling and processing are needed due to reactivity issues. Nonetheless, prepolymers remain indispensable for manufacturing polyurethane products commercially on a large scale.