Polyvinyl chloride, commonly known as PVC, is one of the most widely used plastics globally. It has a variety of applications ranging from pipes and fittings to furniture, flooring, cables, medical devices, and more. This article discusses the properties, production, uses, environmental impact and future outlook of PVC.

Chemical Composition and Properties

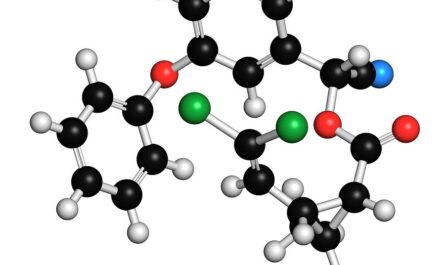

PVC is a thermoplastic polymer made up of 57% chlorine and 43% carbon and hydrogen. The high chlorine content is what makes PVC versatile and durable. It can withstand exposure to chemicals, moisture and microorganisms very well. PVC is also resistant to corrosion and weathering. However, it is not a very strong material and has low flexibility at low temperatures.

Some key properties of PVC include:

– High chemical resistance

– Low permeability to gases and moisture

– Good electrical insulation

– Flame retardant

– Strong and easy to form

– Low production cost

Production of PVC

PVC is produced by polymerization of vinyl chloride monomer which is extracted from petroleum or natural gas. The polymerization process involves heating up vinyl chloride monomers along with initiators and stabilizers to transform it into long polymer chains. Common production methods are suspension polymerization, bulk polymerization and emulsion polymerization.

Global production and consumption of PVC is over 40 million tons annually. The top producers include China, Europe and the United States. Its low production cost, good performance and versatile applications have made PVC one of the most widely used plastics globally.

Major Applications of PVC

Piping and Fittings

Due to its corrosion resistance, durability and low cost, over 35% of total PVC produced is used for pipes, fittings, valves and related products for plumbing, drainage, irrigation and other industrial applications. Its non-reactive nature also makes it suitable for sewerage and potable water distribution systems.

Flooring and Wall Coverings

Flexible PVC sheets are used for commercial flooring, wall coverings, upholstery and vinyl windows owing to their abrasion resistance, affordability and ease of cleaning. Around 15-20% of total PVC is consumed in these applications.

Cables and Wires

PVC’s excellent electrical insulation properties along with resistance to moisture make it ideal for insulated cables and coatings for low voltage applications like electronics, automotive and appliances. Approximately 10-15% of global PVC production is dedicated to cables and wires.

Profiles and Films

PVC is used to produce window profiles, doors, fencing, sheets, films and blister packaging. It accounts for 10-12% of total demand. Features like transparency,printability, chemical resistance and cost effectiveness have made PVC popular choice for these applications.

Medical Devices

PVC’s non-reactive nature and sterilizability using steam or radiation make it suitable for medical devices like tubing, blood bags and other disposable supplies. Around 5% of global PVC is consumed in the healthcare industry.

Others

Remaining applications of PVC include bottles, furniture, auto parts, credit cards, stationery and clothing where its advantages over cost, workability and durability are leveraged.

Environmental Impacts and Sustainability Measures

While PVC has brought many advantages, its production and disposal also pose environmental challenges:

– Production of vinyl chloride monomer and PVC itself are energy intensive and release greenhouse gases.

– PVC contains chlorine which forms hydrochloric acid and dioxins during incineration if burned at low temperatures without proper equipment.

– Chlorine in PVC makes recycling difficult as it hinders decomposition of the material.

– PVC takes a very long period to degrade in landfills if not recycled.

To promote sustainability, major PVC producers have undertaken initiatives like:

– Improving production processes to reduce emissions and energy usage

– Developing new production technologies like suspension polymerization for cleaner outputs

– Using additives to make PVC products recyclable and reusable

– Establishing recycling programs and infrastructure to recover PVC from post-consumer waste

– Promoting use of recycled PVC content in new products

– Investing in R&D for chlorine-free and biodegradable alternative materials

Future Outlook

With growing global population and economic development, demand for PVC is projected to continue rising in the coming decades driven by infrastructure growth and rise of plastic-consuming industries in Asia and Africa. However, more sustainable solutions and policies are needed to manage its environmental footprint over the product life cycle. Continued focus on emission cuts, improved recyclability and alternatives with lower environmental impact will be crucial for PVC to secure its position as a leading plastic material in the future.

Conclusion

In conclusion, PVC has emerged as one of the most widely consumed plastics globally owing to its versatility, durability, corrosion resistance and low cost of production. While it poses environmental challenges, ongoing sustainability initiatives aim to promote its responsible production and end-of-life management. Further technological advancements will determine PVC’s ability to balance performance needs with ecological stewardship going forward.

*Note:

1.Source: Coherent Market Insights, Public sources, Desk research

2.We have leveraged AI tools to mine information and compile it