Photodiode sensors are versatile electronic components that are able to detect light and convert the photons detected into an electrical current. This property makes them useful for a wide variety of applications ranging from light detection to distance measurement. They form the basis of sensors used in security systems, consumer electronics, medical devices and scientific instruments among many other uses.

What is a Photodiode?

A photodiode is a semiconductor device that converts light into an electric current. It consists of a p-n junction made up of positively and negatively doped semiconductor materials such as silicon. When photons strike the photodiode, they transfer their energy to the semiconductor electrons. This gives the electrons enough energy to cross over the p-n junction barrier. The movement of these electrons constitutes a flow of current that can be measured and is directly proportional to the intensity of the incident light.

Main Applications and Uses

Optical communication receivers: Photodiodes are commonly used as optical receivers in fiber optic communication systems. The signal transmitted through optical fibers is detected and converted back into an electrical signal by the photodiode.

Distance measurement: infrared Photodiode Sensors are often used in applications like proximity sensors, laser rangefinders, computer peripherals etc. to measure distance based on the time of flight principle.

Barcode scanners: laser-based barcode scanners employ photodiodes to detect the light reflected back from the black and white bars of a barcode and convert it into a digital signal.

Optical computer mice: photodiodes detect the changes in light reflected from the surface as the mouse is moved to track its position and movement.

Ambient light/proximity sensors: these measure the amount of light around a device to adjust display brightness or turn off the screen when near an object.

Photography: CCD and CMOS image sensors in digital cameras use thousands of photodiode array pixels to capture light and convert it to digital images.

Types of Photodiodes

There are different types of photodiodes distinguished based on their material, structure and operating principles:

– PIN photodiode: Made of lightly doped intrinsic semiconductor layer sandwiched between p-type and n-type layers. Used due to high responsivity and efficiency.

– Avalanche photodiode (APD): Has a high-field region to produce electron/hole avalanche multiplication. Used where gain and sensitivity is important.

– Schottky photodiode: Formed by metal semiconductor junction. Fast response time but low sensitivity.

– Photoconductive diode: Changes its conductivity when illuminated. Useful for light intensity measurement.

– Quantum dot infrared photodiode: For infrared detection using colloidal quantum dots as the absorbing media.

Parameters and Characteristics

Some key parameters to understand the performance and properties of photodiodes are:

– Responsivity: Ratio of output electrical current to input optical power. Higher the better.

– Spectral response range: Wavelength range where photodiode is sensitive. Silicon responsive from 400-1100nm.

– Rise/Fall time: Speed of electrical output response to light input switching on or off. Affects bandwidth.

– Dark current: Current generated without any light. Should be as low as possible to reduce noise.

– Active area: Light sensitive region of the device. Larger area means more light can generate current.

– Breakdown voltage: Maximum reverse bias voltage before device breakdown. Determines operating voltage range.

– Sensitivity: Minimum light power needed to produce detectable electrical output. Depends on active area and responsivity.

Some key performance characteristics are high responsivity, wide bandwidth, low noise, fast response and stability over operational lifetime. Proper selection of type and specifications is required for applications.

Manufacturing and Production Process

The basic photodiode fabrication process involves depositing and doping semiconductor layers on a substrate like silicon wafer. The key steps are:

– Wafer preparation and cleaning: High purity monocrystalline wafers are meticulously cleaned to remove impurities.

– Epitaxial growth: Doping specific layers via processes like CVD to form p-n junction by controlled diffusion of dopants.

– Oxidation: Growing silicon dioxide layer by thermal oxidation to passivate surface and electrical insulation.

– Metallization and Contacts: Evaporating and patterning metal contacts like aluminum.

– Passivation and Anti-Reflection Coating: Final coatings for protection and increased quantum efficiency.

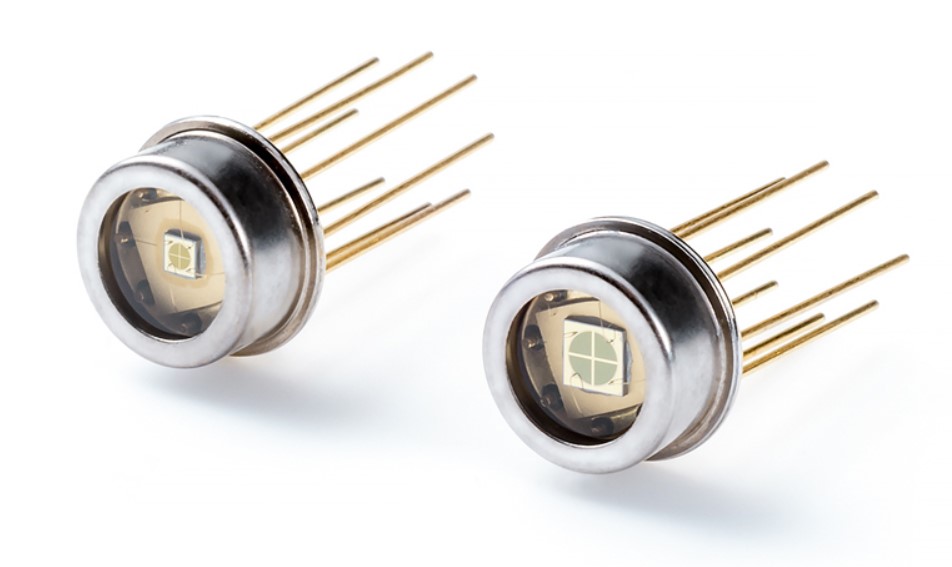

– Dicing and Packaging: Individual dies cut and mounted in protective packages before electrical testing.

Modern fabrication technology enables mass production of consistent, reliable photodiodes efficiently and economically meeting industry demands. Tight quality controls ensure high yields and performance.

Applications of Photodiode Sensors and Future Trends

Photodiode sensors have become ubiquitous thanks to their simple yet versatile photon detection capabilities. Emerging applications include:

– Industrial IoT sensors: Machine vision, quality control, automation, robotics, process monitoring etc.

– Biomedical devices: Pulse oximetry, endoscopy cameras, blood analyzers, surgical imaging tools.

– Consumer electronics: Facial recognition, gesture control, VR/AR headsets, autonomous vehicles.

– Scientific instruments: Astronomy cameras, spectroscopy, laser diagnostics, ellipsometers, microscopy.

Advancing technologies will see new photodiode materials, miniaturized designs, integrated circuit fabrication unlocking more uses. Quantum dot and graphene photodiodes offer potential improvements. The future remains bright for photodiode sensors with the Internet of Things and Industry 4.0 continuing to drive growth. Their photon counting underpins major technologies transforming our world.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it