Over the past few decades, RFID technology has slowly integrated into our daily lives. From supply chain tracking to access control to contactless payment systems, RFID tags provide a way to uniquely identify and track objects electronically. However, traditional RFID tags come with some limitations due to their chip-based design that stores a unique ID number. A new generation of chipless RFID promises to overcome many of these issues by removing the chip entirely.

What is Chipless RFID?

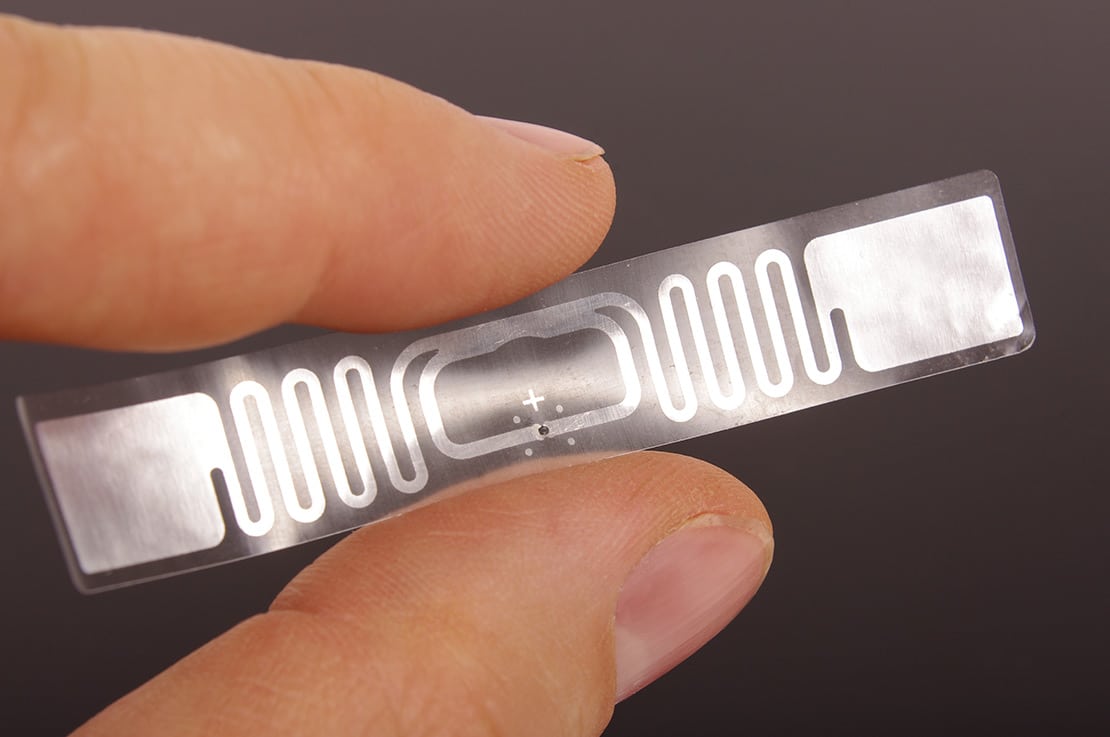

A chipless RFID tag consists of printed patterns or invisible barcodes that can be decoded to retrieve a unique digital identification code without the need for an embedded silicon chip. Unlike traditional RFID tags that require chips, chipless RFID tags are completely chipless and are made from printed patterns or labels that act as radio frequency resonators and can be programmed with identification information. When interrogated wirelessly with radio frequency waves, these coded patterns are able to modulate backscatter signals that contain the identification code embedded in its structural design. The coded response from the tag can then be decoded and processed by a reader to identify and track tags.

The Benefits of Going Chipless

Removing the need for an embedded chip offers several important advantages over traditional chip-based RFID systems:

Cost Savings: The manufacturing cost of chipless RFID tags is vastly lower compared to chip-based tags since they do not require expensive silicon chips. This brings the cost per tag down to fractions of a cent, enabling mass deployment of tags.

Complexity and Size Reductions: By eliminating the chip packaging requirements, the tag structure can be greatly simplified while reducing the overall size well below traditional RFID tags. This enables integration into smaller and harder-to-track objects.

Environmental Friendliness: Chipless tags are fully recyclable, biodegradable and do not contain hazardous materials unlike chip-based tags. This makes them far more environmentally sustainable.

Mass Customization: The coding patterns of chipless RFID tags can be quickly and easily modified during production to enable unique serialization of every single tag, opening up possibilities for tightly tracked personalized products.

Better Read Ranges: Without the power-hungry chip circuitry, chipless tags can achieve longer read ranges compared to passive chip-based tags operating in the UHF frequency range.

Applications of Chipless RFID

Supply Chain Management and Inventory Tracking:

Chipless RFID is highly suitable for tagging individual items in supply chain and inventory management applications due to its low cost of ownership. Mass serialization of products down to component level can enable tightly coupled end-to-end supply chain visibility and automation. Industries like retail, aerospace, automotive are leveraging chipless RFID for use cases involving tracking of parts, containers and palettes throughout the supply chain.

Authentication of Documents and Products:

The unique identification coding of chipless tags enables their use in authentication of important documents and products prone to counterfeiting. Applications involving tagging of currency notes, ID documents, pharmaceuticals to easily verify authenticity electronically is a prime use case. Government agencies are exploring use of chipless RFID for tagging passports and other secure documents.

Access Control and Asset Tracking:

With long read ranges compared to traditional RFID, chipless tags are well-suited for applications involving tracking high-value mobile assets over large areas. Use cases under evaluation include tagging of vehicles, heavy machinery, medical equipment to remotely monitor location and status. The technology also enables advanced access control solutions based on personalized chipless tags.

The Healthcare Opportunity:

Several healthcare applications involving tagging of medical instruments, samples, patients and more stand to gain from the cost and size benefits of chipless RFID. Real-time item tracking within hospitals, matching of blood samples, tagging of newborns are some areas primed for large-scale adoption of the technology. Governments are actively exploring deployment of chipless RFID for electronic health records and identification of citizens.

The Chipless RFID Technology Evolution

Narrowband vs Wideband Chipless RFID:

Early research on chipless RFID focused on narrowband designs that encode information in the radio frequency using basic resonant patterns. While sufficient for basic identification, narrowband tags had limitations in data capacity and read ranges. Modern wideband approaches leverage more advanced coding based on frequency-selective surfaces to significantly increase storage capacity and detection distances to the meter-scale.

Multi-Resonant Tag Designs:

Tag designs have evolved from using just single or dual resonance elements to sophisticated multi-resonant structures that create unique spectral signatures for each tag. Combining multiple resonant frequencies into the same tag footprint aids substantially higher data payloads. Research is also optimizing resonant structures for enhanced backscatter efficiency and miniaturization.

Advanced RFID Reader Technologies:

Commercial viability of any RFID technology depends greatly on reader performance. Recent years have witnessed rapid improvements in reader capabilities like increased multi-tag read rates, higher data throughput, miniaturization and integration of sensing antennas. Advanced signal processing techniques are being applied to effectively decode complex chipless tag signatures, separate multipath distortions and filter noise for enhanced detection distances.

Emerging Interrogation Methods:

Rather than monostatic radar-based approaches, newer interrogation methods leveraging bi-static radar, magnetic induction and near-field RF communications are being investigated for customized chipless RFID solutions suitable for a wider range of environmental conditions. Dedicated research is also addressing deployment, coexistence and security challenges associated with chipless RFID rollouts.

The Road Ahead for Chipless RFID

While immense progress has been made in developing chipless RFID as a practical technology, certain challenges still remain before its mass commercialization and integration into critical infrastructure. Some of the ongoing areas of focus by researchers and industry players include:

– Further miniaturization of tags down to micro/nanoscale for integration into smaller objects and embedding applications.

– Developing reliable tag designs capable of withstanding harsh manufacturing and environmental conditions over long operational lifetimes.

– Increasing RFID data capacities towards kilobits per tag for supporting richer data payloads.

– Expanding read ranges beyond current meter-scale limits for tags operating at low ultra high frequency bands.

– Standardization of protocols, data encoding mechanisms for global interoperability and scalable deployments.

– Security of chipless RFID systems against tag cloning, spoofing and other cyber threats require thorough research.

– Facilitating seamless integration of chipless RFID into existing IoT infrastructure

*Note:

- Source: Coherent Market Insights, Public sources, Desk research

- We have leveraged AI tools to mine information and compile it