Thermal insulation plays a crucial role in regulating temperatures in buildings and industrial structures. It is the process of slowing down or stopping the transfer of heat energy between objects or spaces through various insulating materials. Thermal insulation helps maintain comfortable temperatures inside buildings and improves their energy efficiency by reducing heat gain in summers and heat loss in winters. It prevents the wastage of energy needed for heating or cooling.

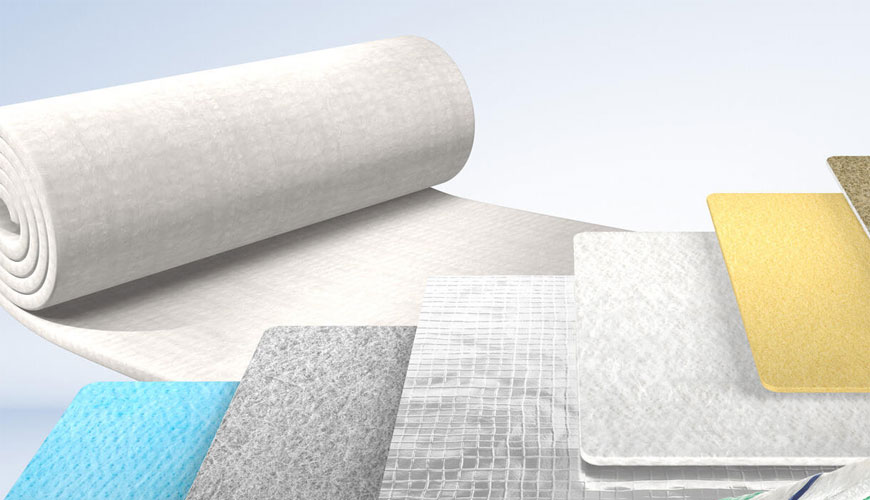

Commonly Used Thermal Insulation Materials

Glass wool: One of the most commonly used Thermal Insulation Materials is glass wool, which is made from fibers of recycled glass. Glass wool provides excellent thermal insulation, is moisture resistant, and economical. It can be used to insulate attics, walls, floors, pipes, and ducts.

Rock wool: Another popular material is rock wool, which is made from natural rock or slag fibers. It has superior fire resistance and high rigidity as compared to glass wool. Rock wool is a good insulator for attics, walls, roofs, and industrial applications involving high temperatures.

Polystyrene: Polystyrene insulation comes in two main forms – expanded polystyrene (EPS) and extruded polystyrene (XPS). It has a closed-cell structure that traps air for effective insulation. Polystyrene sheets and boards provide outstanding resistance to heat transfer and moisture. They are commonly used to insulate floors, foundations, and below-grade walls.

Polyurethane: Spray-applied or poured-in-place polyurethane insulation expands inside wall cavities to form a seamless, air-tight barrier. It has exceptional R-value per inch and adheres well to most surfaces. Polyurethane is ideal for retrofitting older homes and commercial buildings with inadequate insulation.

Fiberglass: Fiberglass insulation consists of fine fibers of glass arranged in an informal lofty structure. It can be formed into loose-fill, blanket, or batt materials. Fiberglass is fire resistant, controls condensation well, and has good sound absorption qualities. It insulates attics, walls, pipes, ducts, and even appliances efficiently.

Cellulose: Made from 80% recycled paper, cellulose insulation offers green insulation. It is blown loose-fill into wall cavities and attics through specialized equipment. Cellulose has high recycled content and R-value. It controls air infiltration, absorbs sound, and resists fire quite effectively.

Other natural insulations include sheep’s wool, cork, hemp, and cotton. Renewable materials like straw bales, denim fibers, and newspaper can also provide insulation. Insulation choices vary based on climate, building type, budget, and sustainability goals.

Thermal Insulation Materials for Walls

Wall insulation plays a major role in thermal performance of buildings as they experience the highest heat transfer. Optimum wall insulation increases indoor comfort levels and lowers heating/cooling costs significantly. Hollow walls in wooden frame buildings allow installation of batt, blown-in or sprayed insulation easily.

Common materials used for wall insulation are fiberglass/rock wool batts, blown cellulose, spray polyurethane foam, and rigid foam boards. Insulation should fill the entire cavity space without gaps or voids. Fiberglass batts are slid between wall studs from the outside or inside. Cellulose can be dense-packed by machines through small drilled holes.

Foam boards come in standard thicknesses to insulate exterior or interior walls. Spray foam creates a seamless air barrier and insulates small gaps and cracks very well. Proper wall insulation enhances the R-value of buildings located in all climate zones. Using high-performance insulations boosts energy efficiency of walls considerably.

Thermal Insulation for Attics

Attic insulation plays an important role in thermal performance of residential and commercial buildings as it forms the topmost layer. Sufficient attic insulation prevents heat transfer between the occupied living areas and the exterior attic roof. Roof designs with inadequate insulation lead to higher energy costs and reduced thermal comfort.

Common types of attic insulation include loose-fill fiberglass/cellulose, rigid foam boards, and rolled/blanket insulation. Loose-fill materials like fiberglass, cellulose or rock wool are blown into attic floor cavities using specialized blowing machines. Installing these to a minimum uniform depth of R-38 (10-12 inches) or more improves efficiency.

Rigid foam boards are also used, either laid over rafters/trusses or sandwiched between them using fasteners. Rolled/blanket insulation like fiberglass batts are another choice for insulating sloped attic roofs. Sprayed polyurethane foams are suitable even for irregularly shaped attics. Proper attic ventilation under eaves prevents moisture buildup beneath the roof decking.

Thermal Insulation Materials Applications in Commercial Buildings

Due to their large sizes and varied functions, commercial buildings have complex thermal insulation requirements compared to households. Effective insulation helps reduce their energy usage and associated operating costs substantially. Insulation standards for commercial spaces are set based on applications like roof installation, wall insulation, pipe wraps, and ductwork.

Some common insulation techniques for commercial buildings are spray polyurethane foam for metal buildings/walls, mineral wool panels for metal deck roofs, rigid board stock for concrete sandwich walls, and radiant barriers for roofs. Perimeter insulation at the base prevents heat loss through structural slabs. Crawl space walls under buildings also require insulated sheathing.

Proper selection of insulation materials like fiberglass, rock wool, XPS and TPO membranes depends on the commercial building type. Insulation products with high R-value and water/vapor resistance insulate places like commercial freezer units efficiently. Paying attention to thermal bridge effects helps provide continuous insulation throughout critical building assembly locations. Tight construction ensures lowered infiltration/exfiltration losses.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research.

2. We have leveraged AI tools to mine information and compile it.