Thermal printing is a digital printing technique that is quickly becoming the industry standard for compact printers. As technology advances at an ever-increasing pace, thermal printing provides a more cost-effective and environmentally friendly alternative to other printing methods. In this article, we will explore the fundamentals of thermal printing, its advantages over other technologies, and the future applications driving its widespread adoption.

What is Thermal Printing?

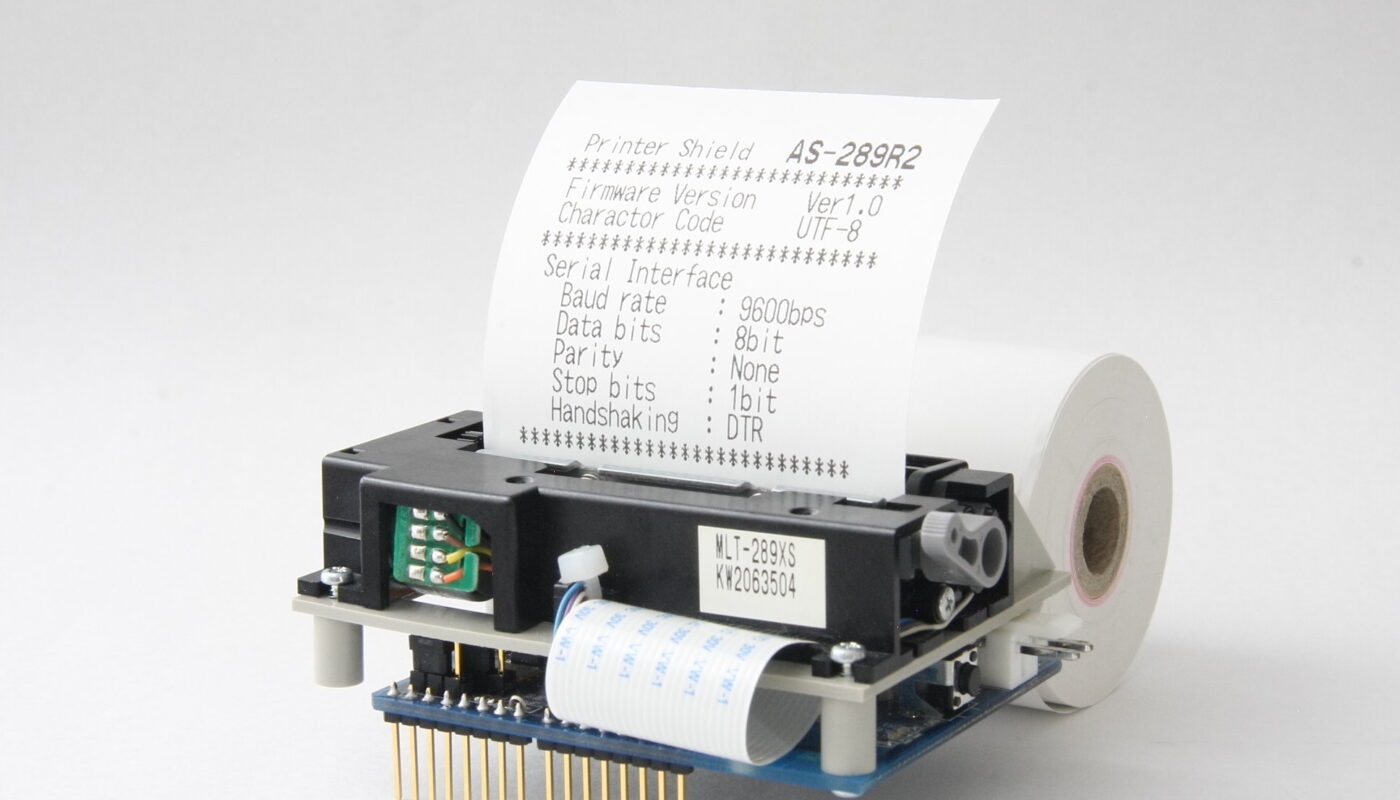

Thermal printing works by applying heat to special heat-sensitive paper or other substrate like tags or labels. Thermal Printing heads contain a line of small heating elements that are selectively heated to cause a chemical reaction on the special thermal paper. No ink is needed as the paper darkens when heat is applied.

Thermal print heads are composed of a row of miniature heating elements. Each element is independently controlled to heat spots on the paper as it passes over the print head. The heat causes a reaction in the coating on the paper, making it turn black at the heated spots and leaving white areas where no heat was applied. This allows complex images, text and barcodes to be quickly rendered without using liquid inks.

Advantages Over Inkjet and Laser Printing

Thermal printing offers several key benefits over traditional inkjet and laser printing technologies:

– No Ink Needed – Thermal printing uses solid state technology with no liquid inks required, simplifying maintenance and reducing costs.

– Instant Dry Time – Images printed using thermal technology dry instantly without need of drying time. Text and images can be handled immediately.

– Compact Size – The lack of ink cartridges and other components allows thermal printers to be much smaller, with many designed for portable use.

– Durability – Thermal printed labels and receipts can withstand moisture, chemicals, and abrasions better than inkjet due to properties of thermal paper.

– Low Power Usage – Thermal print heads consume less power than laser printing mechanisms or piezoelectric inkjet print heads.

– Environmentally Friendly – Thermal printing is an essentially “green” technology with no solvents, chemically treated cartridges, or other e-waste associated with it.

– Reliability – Thermal print heads have no moving parts and last significantly longer than ink cartridges, reducing long term costs of ownership.

– Low Cost of Operation – The combination of low power usage, lack of consumables, and long print head life results in extremely low cost per printed page.

Applications and Future Growth

Point of Sale and Retail Receipts

Thermal printing is now the established standard for POS receipt printing worldwide. Its cost advantages, reliability, and instant drying make it ideal for busy retail environments. Thermal technology prints over 90% of all retail receipts globally.

Logistics and Shipping Labels

Warehouse and distribution center labeling is another huge application area. Labels for packages, pallets, containers etc are predominantly printed using thermal printers. Features like durability in all weather, resistance to moisture and chemicals are well-suited.

Industrial Applications

Beyond retail and logistics, thermal printing finds growing use in industrial environments. Applications include product identification labels, work instructions, quality assurance signage and more where durability and ruggedness are important.

Healthcare and Medical Records

Thermal technology is also making headway in the healthcare industry. It prints diagnostic reports, patientcharts, prescriptions and wristbands. Features like HIPAA compliance, resistant paper and small printer sizes suit many point of care uses.

Future Potential and Opportunities

While already entrenched in some verticals, thermal printing is expected to continue eating away market share traditionally held by inkjet and impact printing. Some potential growth areas on the horizon include:

– Mobile and Portable Printing – Miniaturization will expand uses of rugged, low power thermal printers in mobile devices and field applications.

– Sensors and “Smart Labels – Advanced papers and integration with sensors/ electronics could enable “smart labels” with interactive or logistical functions.

– New Applications – Innovations in substrates could enable new uses like flexible/textile printing or even direct thermal printing on surfaces like wood or plastic.

– Industrial Automation – Integration with IoT/factory automation presents opportunities for real-time product tracking, maintenance records and more within manufacturing environments.

Thermal printing technology has evolved rapidly since its origins and continues powering ahead. It offers significant advantages for applications where reliability, mobility and low operational costs are important factors. With a bright future ahead driven by new innovations and expanded use cases, thermal looks poised to further cement its position as the dominant digital printing method.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it