Cyanate ester resins are a class of thermosetting polymers that are gaining popularity as high-performance composite matrices. They offer outstanding mechanical, thermal, and electrical properties making them well suited for applications where performance is critical.

Chemical Structure and Curing Reaction

Cyanate ester resins are formed by reacting bisphenols with cyanogen halides. The resulting monomers contain cyanate ester functional groups (-OCN). One of the most common cyanate ester monomers is bisphenol-E dicyanate.

During the curing or crosslinking reaction, the Cyanate Ester Resins groups trimerize to form triazine rings. This occurs via an addition-elimination mechanism when heat is applied. The reaction is catalyzed and the rate is dependent on both temperature and catalyst concentration. Common catalysts include tertiary amines and imidazoles.

Once the triazine rings form, they act as crosslinking sites that create a highly crosslinked, three-dimensional thermoset polymer network. The high degree of crosslinking results in exceptional properties and performance compared to other thermosetting polymers like epoxies.

Key Properties

The dense, crosslinked structure of cyanate ester resins leads to outstanding thermal, mechanical, and electrical properties. Their glass transition temperature ranges from 250°C to 350°C, making them highly thermostable. They retain their mechanical properties and dimensional stability up to 200-225°C.

Cyanate Ester Resins demonstrate high strength and stiffness comparable to other high-performance thermosets. Their compressive and tensile strengths are high, and they exhibit excellent fatigue resistance. Perhaps their most useful property is their near-zero water absorption, which leads to maximum dimensional stability and little property degradation over time.

Electrically, cyanate esters have very low dielectric constants and losses, making them well-suited for electronic applications. Their coefficient of thermal expansion is also very low and tunable. These properties make cyanate esters attractive for applications where thermal cycling, vibration resistance, and dimensional stability are priorities.

Processing Techniques

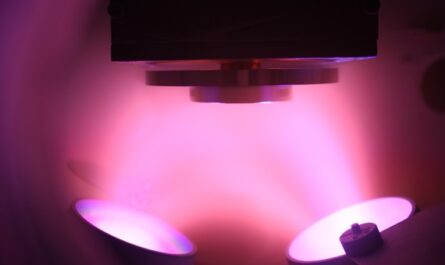

Given their thermosetting nature, cyanate esters must be processed and cured using heat. Sheet molding, bulk molding, resin transfer molding (RTM), and vacuum-assisted resin transfer molding (VARTM) are common processing techniques for composites.

In sheet molding, the resin is supplied in sheet form which is cut, laid into a mold, and then cured. Bulk molding uses bulk cyanate ester resin that is metered and blended with fillers before molding. RTM and VARTM injection mold the liquid resin system under vacuum into a dry fiber reinforcement component.

For all techniques, the composite part is cured using a two-stage heat cure cycle. An initial low temperature stage fully polymerizes the resin, and a final high temperature post-cure further crosslinks the material. Cure times range between 2-16 hours depending on part geometry and desired properties. Careful oven temperature control is required to maximize performance.

Applications

Due to their impressive mechanical, thermal, and electrical properties, cyanate ester resins are increasingly adopted in demanding composite applications. Some key areas of use include:

– Aerospace structural components – Wings, fuselages, radomes, and engine nacelles benefit from cyanate ester’s heat and impact resistance.

– Electronic printed circuit boards – Their low dielectric properties make cyanate esters attractive for lightweight, high-speed circuit boards.

– Marine vessels – Propellers, rudders, water tanks, and other marine parts have stringent durability needs met by cyanate esters.

– Oil and gas infrastructure – Pipe casings, pump impellers, and valves in downhole and offshoreenvironments perform reliably for long lifecycles.

– Wind turbine blades – Their strength, stability, and long working lifetime fit the needs of modern wind energy generation technology.

– Motorsports – High-performance auto and motorcycle components demand materials as robust as cyanate ester resins.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it