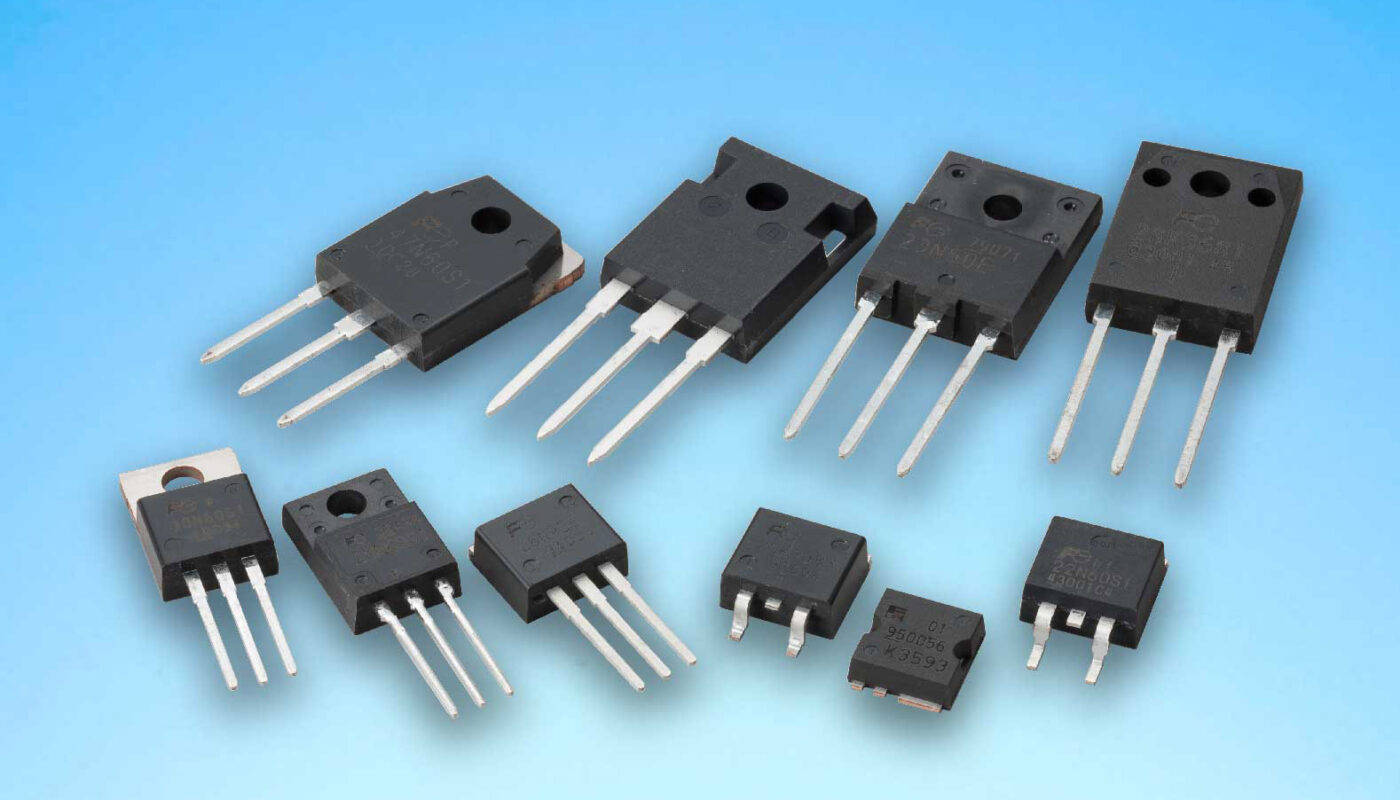

With the advancement of power electronics and growing demand for energy efficient solutions, power semiconductor devices play a crucial role in wide range of applications from renewable energy to electric vehicles. Two most commonly used power devices are Insulated Gate Bipolar Transistor (IGBT) and Super Junction MOSFET. In this article, we will discuss the working principle, characteristics and applications of IGBT and Super Junction MOSFET.

IGBT – The Workhorse of Power Electronics

The IGBT And Super Junction MOSFET Transistor is one of the most widely used power semiconductor devices. It was developed to combine the simple gate-drive characteristics of the MOSFET with the high current and low saturation voltage capabilities of bipolar junction transistor (BJT).

An IGBT consists of an insulated gate field-effect transistor with an embedded bipolar junction transistor. When positive voltage is applied to the gate terminal, an N-type inversion layer is created due to the field-effect allowing current to flow between the emitter and collector terminals. At the same time, the bipolar transistor action is initiated by the emitter-base junction which helps in further amplification of the device current.

The key advantages of IGBT include high input impedance, ease of gate drive, fast switching, high current & power handling capability. Due to these properties, IGBTs are extensively used in industrial motor drives, variable frequency drives (VFDs), electric vehicle motor drives, renewable power converters, uninterruptible power supplies and even transformerless grid-tie inverters. IGBT modules with ratings of 6500V/1200A are widely available today for different power electronics applications.

Evolution of IGBT Chips

Over the years, IGBT chip technology has continuously evolved with new structures being introduced to enhance its performance. Early IGBTs had a simple planar structure but later trench gate and field stop IGBT chips were developed to reduce conduction and switching losses. In trench gate IGBT, the gate electrode is wrapped around the silicon body in a trench instead of planar structure. This increases the effective gate area and thus reduces the on-state voltage drop.

Field stop IGBT and Super Junction MOSFET structure lowers the switching losses by reducing the minority carrier lifetime in the drift region through additional ion implantation. The super junction IGBT structure further improves the specific on-resistance by introducing periodic pillar of alternate dopants to replace the lightly doped drift region. The latest dual lifetime control IGBT combines the advantages of both field stop and super junction structures to optimize the conductivity modulation and switching performance.

Super Junction MOSFET – An Alternative to IGBT

While IGBT remains dominant for medium to high power applications, Super Junction MOSFET provides a worthy competition in a few areas. A Super Junction MOSFET has a multi-resistive layered epitaxial drift structure formed by alternate P and N columns that enable high breakdown voltage in a very narrow silicon area.

Due to this unique structure, Super Junction MOSFET exhibits nearly half the on-state resistance of IGBTs at the same voltage rating. As a result, it offers lower conduction losses compared to IGBTs. Also, the gate terminal is completely insulated from the power flow path allowing simpler gate drive circuits. The operational switching speed of Super Junction MOSFET is higher than IGBT which reduces the switching losses.

These superior characteristics have enabled Super Junction MOSFETs to replace IGBTs in lightweight compact converters below 500V/100A rating typically used in server power supplies, telecom rectifiers, solar micro inverters and battery chargers where high efficiency is critical. The manufacturing cost of Super Junction MOSFET is also lower than IGBT at lower power levels. However, scaling Super Junction MOSFET to higher current and voltage levels remains challenging.

Comparing IGBT Vs Super Junction MOSFET

To summarize the comparison between these two prominent power devices:

– Breakdown Voltage: IGBT provides higher voltage blocking capability up to 6500V versus 900V maximum for Super Junction MOSFET.

– On-resistance: Super Junction MOSFET has up to 50% lower on-resistance than IGBT at the same voltage rating.

– Switching Speed: Super Junction MOSFET is faster with switching times under 100ns while IGBT is in microsecond range.

– Gate Drive: Super Junction MOSFET has simpler gate drive requirement without need for elevated gate voltage.

– Current Rating: IGBT options are readily available with current rating over 1200A but Super Junction MOSFET scales poorly above 100A.

– Cost: At higher power levels, IGBT has lower production cost per amp compared to multi-resistive Super Junction MOSFET structure.

IGBT will continue dominating the medium to high power range in applications like motor drives, renewable energy converters due to its higher voltage and current handling capability. On the other hand, Super Junction MOSFET provides a better option for low to medium power systems below 500V/100A requiring high efficiency due to its low on-resistance characteristic. Both these devices have a bright future in further penetration of power electronics in sectors like electric vehicles, renewable energy resources and energy efficient systems.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it.